Tubolitos are made of TPU. Due to innovative processing of this special material, Tubos are not only significantly lighter, but also more robust than classic tubes made of butyl rubber.

Tubos are about twice as robust as classic inner tubes made of butyl rubber.

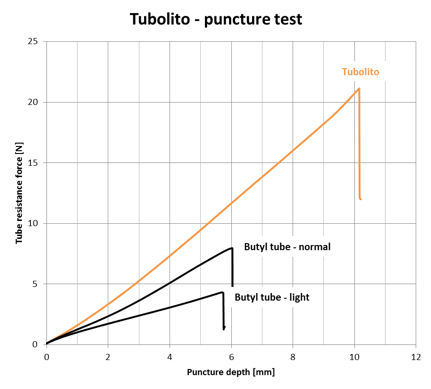

An important and frequently used parameter to test the puncture resistance of a bicycle inner tube is the needle puncture test. It measures the force required to puncture a bicycle inner tube with a test mandrel.

The test shows: To puncture a tube of the Tubo-MTB series, about twice as much force is required as with conventional products made of butyl rubber.

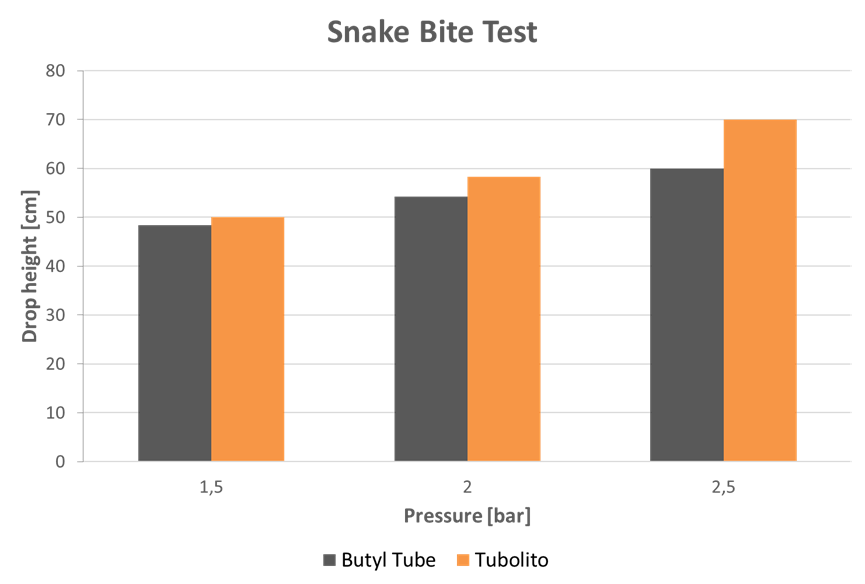

In terms of snake bite damage to the bicycle tube, Tubolitos have similar characteristics as rubber tubes.

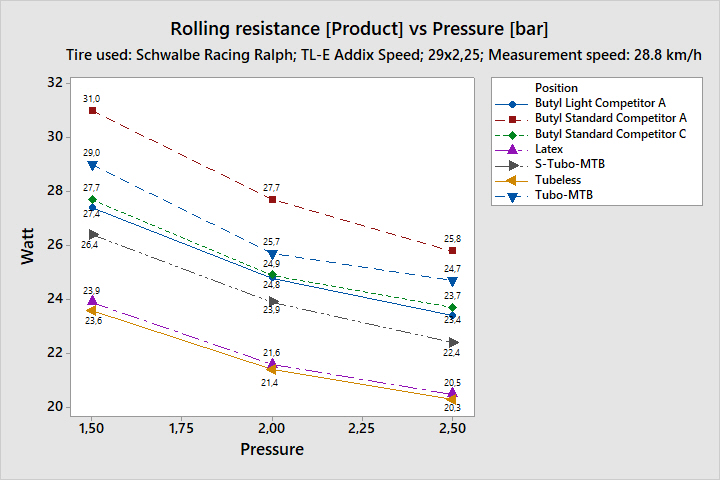

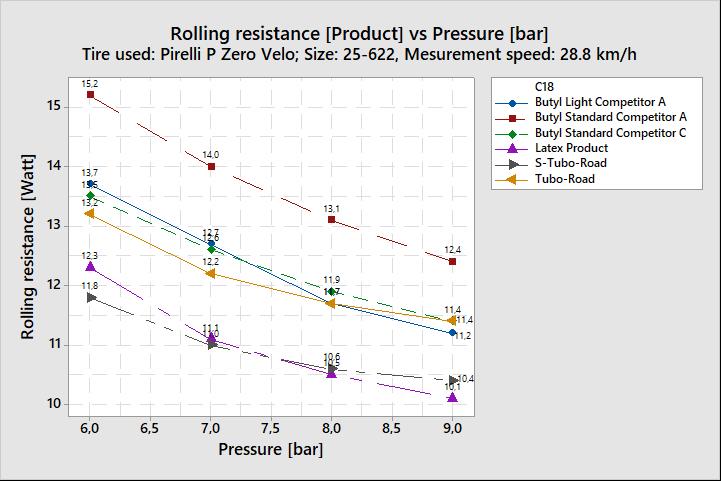

We have had the rolling resistance of our products tested by an independent body. The following graphs show the results:

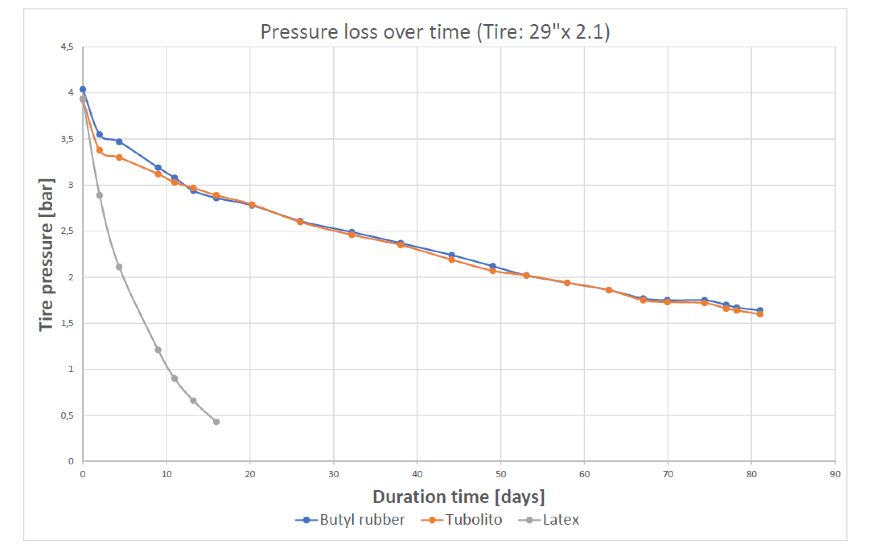

As the graph below indicates, Tubos have similar characteristics concerning air retention as rubber tubes.

The maximum and minimum air pressure for using Tubolitos depends on the tire being used. Please always follow the pressure specifications provided on the tire.

Important: Tubolitos must not be inflated to more than 0.5 bar / 7 psi when outside the tire. Overinflating them outside the tire can lead to deformation and damage.

Yes, but as with butyl rubber tubes, CO2 escapes more quickly than air, so that the tubes have to be reinflated sooner.

Yes — if a puncture occurs, you can easily repair the inner tube using our specially developed Tubo-Patch Kit, designed specifically for TPU tubes.

Important: Repair kits made for butyl rubber tubes are not compatible with Tubolitos.

Only Tubolitos with Schrader/AV valve are compatible with sealants and repair sprays as the valve core is removable.

The valve cores of Tubolitos with Presta/SV valves are glued in and therefore sealant or repair sprays cannot be inserted.

We performed tests with different products:

Sealant: Oko Puncture free Bike

Repair Spray: Nigrin Reifendicht; Vittoria Pitstop Super Magnum; Tip Top Pannenspray; Güp Kwiki

Residues of tubeless milk do not harm Tubolito products.

To see our full product range, please visit the “PRODUCTS” section on our homepage. However, we are constantly testing and developing new ideas and innovations. Information about new products is posted on our homepage and on our social media channels.

You can find more details about the dimensions of Tubolitos on: www.tubolito.com/sizing

Tubo: The perfect tube for everyday use – more robust and lighter than a conventional butyl tubes. Combining performance and durability, it’s the smart upgrade for any bike.

S-Tubo: Light as a feather and compact due to reduced wall thickness – extremely low rolling resistance. Perfect as a spare tube. S-Tubos achieve very similar results in the needle puncture test as much heavier rubber tubes.

X-Tubo: No Flat Tube – extremely durable. Designed for everyday riding with maximum resistance to punctures and includes a 1-year replacement policy for registered X-Tubos on our website.

To see our full product range, please visit the “PRODUCTS” section on our homepage. There you can check if the Tubolito is ready for disc and rim brakes.

Tubolitos comply with the test according to DIN 4210 (15 minutes of continuous braking with max. 10×10 seconds interruption) with both aluminium and carbon rims.

Doing a disruptive test, meaning braking as long till the product fails, shows that Tubolitos, unlike tubes made of butyl rubber, do not loose air explosively, but slowly over several minutes.

Standard pump heads require at least 15 mm of valve to remain above the rim for proper inflation. To choose the correct valve length, use this simple rule:

valve length – rim height ≥ 15 mm

So, subtract your rim height (in mm) from the valve length (in mm). If the result is 15 mm or more, the valve will work with standard pump heads.

The Presta valve cores are glued in and therefore cannot be removed.

We performed tests with “Topeak Presta Valve Extender Series” valve extensions and our valves are completely tight with them.

Yes, as long as the dimensions of the tire (wheel diameter and width) are the same, you can remount the tube without any issues.

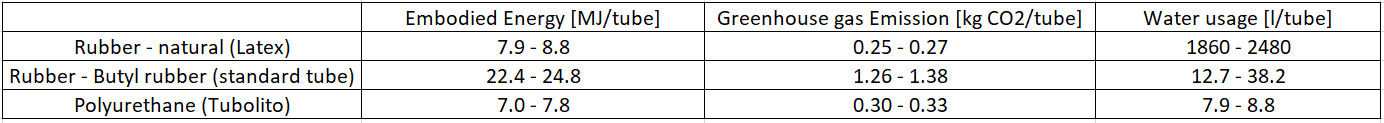

The production of the raw material for an 85-gram Tubo-MTB-29 requires around 7 MJ of energy and emits around 0.3-0.33 kg of CO2. In comparison, the production of the raw material for a standard butyl tube weighing about 200 grams emits 1.26-1.33 kg of CO2 and requires about 22 MJ of energy. The graph below shows that the water consumption for the production of the raw material for Tubolitos is also significantly lower compared to the production of the raw material for inner tubes made of other materials.

Citation: M.F. Ashby, Materials and the Environment – ECO-Informed Material Choice, 2nd edition, Butterwoth-Heinemann, plus accompanying CES EDUPack Software

As pioneers in the field of TPU bicycle inner tubes, we wanted to also visually highlight the innovative character and nature of Tubolitos compared to conventional bicycle inner tubes made of black butyl rubber.

Site design by Fargo Circle. Built by TRWD

In case we ask you to submit product information about your Tubolito for quality review purposes, please send us the following two codes.

Step 1. Finding the Product Code of your Tubolito:

The product code is a 9 digit code next to the Tubolito logo on your tube.

In the example picture: 907111206

Step 2. Finding the Batch Code of your Tubolito:

The batch code is made up of 4 or 5 digits and a letter and is printed right underneath the name of your Tubolito.

In the example picture: 19465A

Thank you for your help and we hope you continue to enjoy using